The Tickle College of Engineering’s Office of Engineering Professional Practice recently held its annual fall expo, once again setting records for the number of students, businesses, and organizations participating.

“The Engineering Expo is our premier on-campus recruiting event,” said director Todd Reeves. “Employers look to us to help UT engineering students participate in their cooperative education and/or internship educations assignments in their organizations.”

The expo gives students and employers a chance to meet on day one, followed by interviews where there was common interest on the second day.

This fall, 93 employers came and spoke with 972 students, resulting in more than 1,200 interviews being scheduled. Five years ago, by comparison, there were 59 employers and 478 students participating.

Reeves said that his office tries to match students with employers that are closely aligned with their academic work and career goals. All of the positions UT students take are paid, meaning students earn an income while furthering their studies with practical, real-world experience.

“Nearly 45 percent of our graduating seniors each year have participated in our program,” Reeves said, “The expo is the primary engine that drives the connection between students and companies each semester.”

The Office of Engineering Professional Practice was founded in 1926 and is the second oldest program of its kind in the south, and one of the oldest in the nation.

The featured student this week is Austin Winstead, a mechanical engineering major from Nashville, Tennessee, who worked for Brasfield & Gorrie in Birmingham, Alabama.

The featured student this week is Austin Winstead, a mechanical engineering major from Nashville, Tennessee, who worked for Brasfield & Gorrie in Birmingham, Alabama.

The featured student this week is Jessica Ossyra, a Chemical and Biomolecular Engineering major from Knoxville, Tennessee, who worked for SI Group in Newport, TN.

The featured student this week is Jessica Ossyra, a Chemical and Biomolecular Engineering major from Knoxville, Tennessee, who worked for SI Group in Newport, TN. The featured student this week is Tanner Hardin, an electrical engineering major from Knoxville, Tennessee, who worked for SABIC Innovative Plastics in Mt. Vernon, Indiana.

The featured student this week is Tanner Hardin, an electrical engineering major from Knoxville, Tennessee, who worked for SABIC Innovative Plastics in Mt. Vernon, Indiana. The featured student this week is Yishmael LaMay, a chemical engineering major from Franklin, Tennessee, who worked for Shaw Industries in Dalton, Georgia.

The featured student this week is Yishmael LaMay, a chemical engineering major from Franklin, Tennessee, who worked for Shaw Industries in Dalton, Georgia.

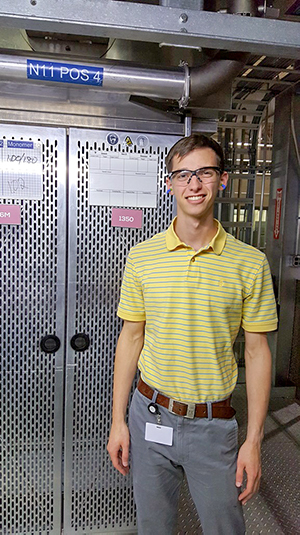

The featured student this week is Ethan Weaver, a Mechanical Engineering major from Spring Hill, Tennessee, who worked for

The featured student this week is Ethan Weaver, a Mechanical Engineering major from Spring Hill, Tennessee, who worked for