Eli Callendar, a senior in mechanical engineering, spent time this summer working as a Maintenance Engineering intern for Nissan in Smyrna, TN. Callendar learned valuable project management and collaborative skills during his experience working with a world leader in automotive manufacturing.

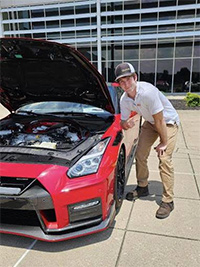

Eli Callendar, a senior in mechanical engineering, stands next to a red Nismo GTR.

My name is Eli Callender. I am a senior studying Mechanical Engineering at the Tickle College of Engineering. I was fortunate enough to work as a Maintenance Engineering Intern this past summer at Nissan’s manufacturing plant in Smyrna, TN. Nissan is a household name, and their vehicles can be seen on the road every day all around the world. Based in Japan, Nissan has been creating automobiles that live up to their slogan, “Innovation that excites,” since 1933 and has been producing vehicles in Smyrna since 1983.

As an intern at Nissan, I was placed in the Paint Line 1 area of the plant among the engineers, managers, supervisors, and technicians located there. I worked closely with the technicians throughout most days and was able to learn how the machinery in the painting process operated and was maintained. Having spent most of my education in a classroom, it was exciting to get the opportunity to have hands on experience with the equipment and processes that I had studied, and even a lot of equipment I had never imagined, such as a giant 6-axis feather duster robot. When I wasn’t working with the technicians, I was shadowing the engineers and supervisors as they carried out their tasks. Through these interactions, I gained insight and knowledge of responsibilities such as managing groups of people in industry, working with contractors to install new equipment, and even looking at design blueprints to reengineer something that is not working properly or needs improvement. I was given a few projects over the summer including working with contractors to do a large installation project for improvements in the paint booths, designing an aide to help better support technicians working with some of the robots on the line, and designing a countermeasure to prevent a major breakdown incident from reoccurring. Nissan also provided several events that allowed the interns to meet one another and learn more about the company, including driving the famed Nismo GTR and their newest 400Z.

Overall, I would recommend any opportunity to learn and work for Nissan. The company has a great culture, great people, and great processes to make great vehicles. I look forward to using the skills and connections I gained from my time at Nissan as I continue my studies and career. To learn more about internships like mine, stop by the Engineering Professional Practice Office (EPP) or the Reliability and Maintainability Center (RMC).