Student Spotlight: Thomas Scott

Mechanical engineering major Thomas Scott completed an internship with Lawrence Livermore National Lab during the summer 2023 semester.

Student Spotlight: Ian Tulk

Aerospace engineering major with mechanical minor Ian Tulk completed an internship with Honda Development Manufacturing America in Lincoln, Alabama.

Student Spotlight: Christopher Schenck

MABE student Christopher Schenck completed a valuable co-op assignment, working for the largest logistics company in the world, the United Parcel Service.

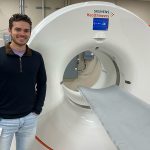

Student Spotlight: Camden Shuman

Mechanical engineering junior Camden Shuman gained valuable experience while participating in a coop work program with Siemans Healthineers.

Student Spotlight: Eli Callendar

Eli Callendar, a mechanical engineering senior, discusses the skills and processes he learned while participating in a summer internship at Nissan.

Student Spotlight: Zachary Koller

MABE senior Zachary Koller learned and applied industry relevant skills during his co-op experience with Beehive Industries in Knoxville, TN.

Student Spotlight: Adam Schoolfield

During his co-op experience, MABE senior Adam Schoolfield gained valuable skills and practical, hands-on work experience while serving as a Manufacturing Engineer at JTEKT Vonore.

Student Spotlight: Jake Orr

Jake Orr, a MABE rising sophomore, worked with unmanned aircraft to improve military safety during his coop experience at Aim Lock, Inc.

Student Spotlight: Donovan Stockdale

MABE student Donovan Stockdale, a senior in mechanical engineering, speaks about his internship and the experience he gained throughout that time.

Student Spotlight: Russell McCoig

Civil and environmental engineering student Russell McCoig co-oped in Louisville, Kentucky from January-December 2022 with EMJ Construction.